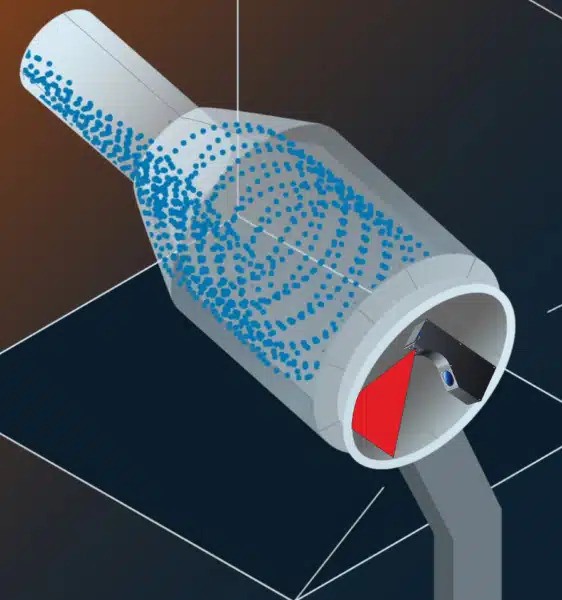

Innovative Energy Generation: Solar Thermal Power Plants as the Key to Efficient Energy Storage. The German Aerospace Center (DLR) is researching and testing this technology in collaboration with industrial partners. The QuellTech Q6 laser scanner is utilized to non-invasively measure the thickness of ceramic particle layers.In a pioneering approach, the QuellTech Q6 laser scanner contributes to achieving an optimal configuration of these particles. The scanner’s capacity to accurately measure the rotating drum, where ceramic particles are employed for heat storage, allows for precise monitoring. This integration not only accelerates projects but also ensures quality assurance by identifying irregularities in drum rotation and compensating for them through meticulous adjustments.